Looking for the right 3LPE coated pipe? Want to find a quality 3LPE coated steel pipe supplier? Keep reading—TUSPIPE understands your needs! We’ll not only explain what 3LPE coated pipe is but also provide premium solutions!

What Is 3LPE Coated Pipe

The Evolution of Triple-Layer Extruded Polyethylene Coated Pipes

Before the mid-20th century, coated pipes used petroleum asphalt or coal tar enamel as anti-corrosion coatings. These coatings are low in cost, but their obvious drawbacks are poor thermal stability and insufficient mechanical strength.

Subsequently, single-layer polyethylene (PE) coatings brought some progress. Though offering chemical resistance and excellent insulation, they failed to bond well with the inner steel pipe. Internal corrosion frequently occurred in such coated pipes.

In the 1960s, FBE coated pipes gained widespread adoption. They achieved exceptional adhesion between the pipe and the fused epoxy powder coating. However, the 250-500μm chemical coating thickness was insufficient to provide adequate protection for the underlying steel pipe.

The three-layer polyethylene (3LPE) coated pipe integrates and improves upon both single-layer polyethylene and FBE coatings. It combines the advantages of both while dividing the coating into three distinct layers: the first layer (base coat) uses FBE, the second layer (intermediate coat) employs a polymer adhesive, and the third layer (top coat) utilizes high-density polyethylene. This synergistic three-layer system enables 3LPE coated pipes to withstand harsh conditions like long-distance transmission and high-pressure environments, making them the global standard for corrosion-resistant coated pipelines.

3LPE Coated Pipes Corrosion Protection Principle

3LPE coated pipes are also known as 3PE coated pipes.

Their three-layer structure achieves collaborative protection through distinct functions:

Epoxy Powder Base Coat (FBE): The epoxy powder base coat (FBE) serves as the first layer on the steel pipe substrate. It directly isolates the pipe surface from corrosive media like water and oxygen. Applied via electrostatic spraying, it forms a protective layer approximately 150-350 microns thick. This first layer provides excellent adhesion strength, safeguarding the steel pipe even under deformation without coating detachment.

Polymeric Adhesive Intermediate Layer: Positioned between the epoxy layer and the polyethylene layer, the polymeric adhesive features polar groups at one end that form chemical bonds or strong hydrogen bonds with the epoxy’s active groups. The other end consists of non-polar segments highly compatible with polyethylene, achieving a robust bond through molecular chain diffusion and entanglement.

Extruded Polyethylene Outer Layer (PE): As the outermost layer of 3LPE-coated pipes, this uses high-density or medium-density polyethylene material with a thickness of 1.5 to 3.0 millimeters. This material reduces water vapor permeation through the steel pipe, offering excellent scratch resistance and flexibility.

The synergy of the three structural layers enhances the anti-corrosion performance of the pipeline. If you need 3LPE Coated Steel Pipe, please contact us immediately!

3LPE Coated Pipes Supplier / Manufacturer

As a leading global steel pipe manufacturer, TUSPIPE provides 3LPE coated pipes and solutions with exceptional corrosion resistance. We help you maximize cost efficiency and extend project lifespans. We also offer a variety of anti-corrosion coated pipes, allowing you to select the most suitable option for your project requirements. Contact us for solution discussions and quotations!

3LPE Coated Pipes Manufacturing Process

- Surface pre-treatment: After heating the steel pipe to eliminate residual moisture, sandblasting is performed. The surface exhibits a uniform metallic finish. Cleanliness and roughness metrics are verified through inspection, enabling rapid progression to the next stage to prevent secondary oxidation and rusting of the steel surface.

- FBE spraying: Steel pipes are heated to 200-240°C before applying epoxy powder via electrostatic spray guns. Heating temperatures are strictly controlled throughout this process to prevent incomplete powder curing or thermal aging/degradation of polymer materials.

- Adhesive and PE synergy: Adhesive molecules chemically react with or physically permeate the FBE layer while simultaneously intertwining with PE molecular chains at the opposite end. This achieves seamless bonding between the distinct properties of FBE and PE.

- Cooling and curing: The coated pipe is cooled at a controlled rate to prevent residual stress concentration within the polyethylene shell.

- End treatment: Uncoated sections are left at both pipe ends and sealed using liquid epoxy material.

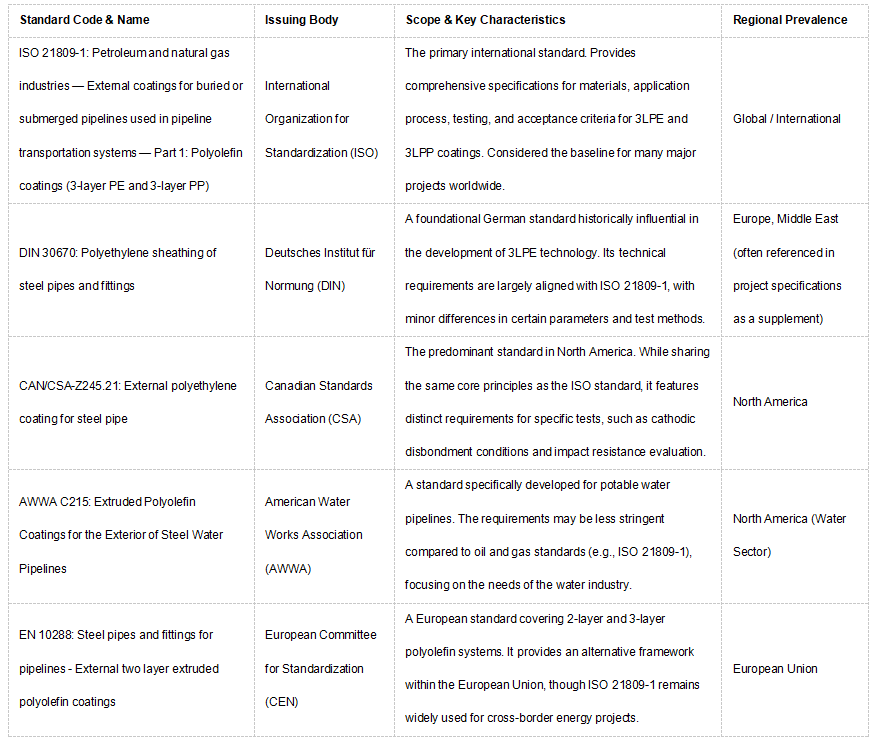

3LPE Coated Steel Pipe Compliance Standards Chart

TUSPIPE’s 3LPE coated pipes are manufactured in strict adherence to international standards. We rigorously control quality to exceed specifications, ensuring every steel pipe meets the highest standards!