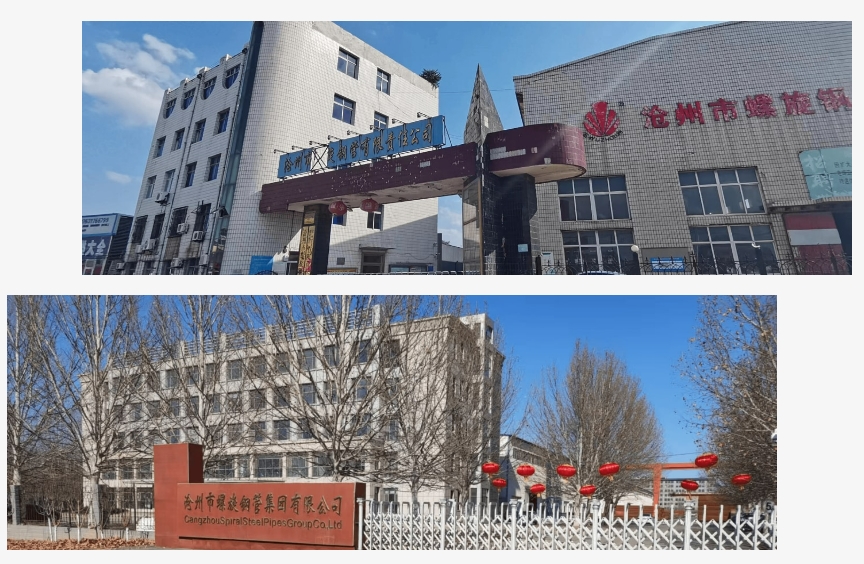

At WUZHOU, we operate two state-of-the-art manufacturing plants designed to meet the highest standards of production. Our facilities are equipped with cutting-edge technology and advanced machinery to ensure optimal efficiency and product quality. Below are some photos of our factory and production workshops.

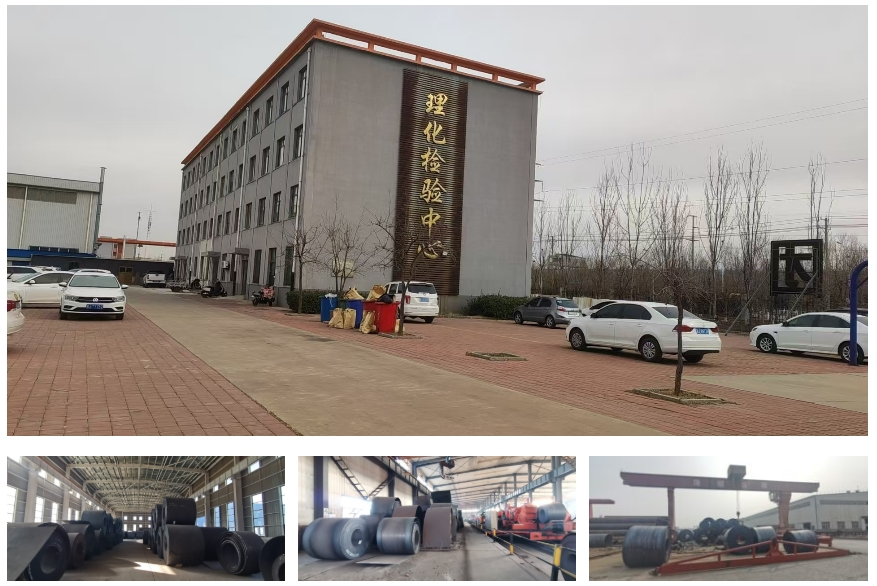

At WUZHOU, the quality of our spiral steel pipes begins with the selection of premium raw materials. We understand that the foundation of every high-quality product lies in the materials used. That’s why we only source top-grade steel coils, ensuring that each pipe we produce meets industry-leading standards.

At WUZHOU, we use the latest in production technology to create high-quality spiral steel pipes. Our state-of-the-art equipment ensures precision, efficiency, and superior product quality, all while adhering to the highest industry standards.

Smoothly unwinds steel coils for consistent material flow, reducing strain during production.

Shapes steel strips into precise spiral forms, ensuring structural integrity.

Creates smooth bevels on pipe edges for secure and strong welds.

Cuts pipes to exact lengths, reducing material waste and ensuring size accuracy.

Applies an internal protective layer to improve corrosion resistance.

Applies an exterior protective coating to safeguard pipes against environmental damage.

Conducts pressure tests to confirm the strength and leak resistance of the pipes.

Uses sound waves to detect any internal inconsistencies, ensuring the pipes are free from defects.

Inspects the internal surface of pipes for any defects using industrial-grade TV technology.

Once the production and testing processes are complete, our spiral steel pipes are packaged and prepared for delivery. Port of departure:TianJin Port, HuangHua Port.