WUZHOU is the leading brand of Cangzhou Spiral Steel Pipes Group, specializing in high-quality spiral welded steel pipes for oil, gas, water, and power industries. Manufactured to international standards with premium steel grades, WUZHOU pipes ensure strength, durability, and performance. Recognized as a “Top 10 Chinese Brand of Steel Pipe”, WUZHOU stands for quality and reliability.

Discover our premium spiral weld pipe solutions, designed for durability and efficiency across diverse applications.

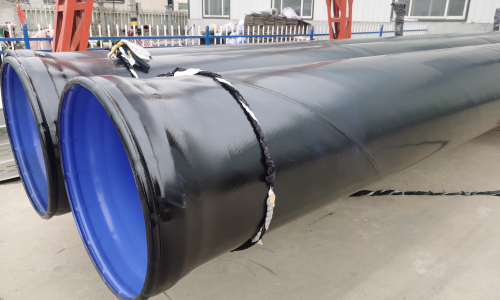

Enhanced with protective coatings for superior corrosion resistance and longevity.

Engineered with internal linings for improved flow efficiency and chemical resistance.

High-strength welded pipes, ideal for structural and fluid transportation applications.

Our spiral steel pipes are manufactured to meet the highest international standards, ensuring superior performance, safety, and reliability across industries.

Our spiral steel pipes are manufactured to meet the highest international standards, ensuring superior performance, safety, and reliability across industries.

Our company is the largest provider of steel water pipe manufacturing spirally welded pipe, rolled-and-welded straight seam pipes for the water market in diameters of 14-inch through 146-inch.

Read More

SSAW (also known as SAWH) steel pipe refers to spiral welded seam submerged arc welded steel pipe. The production process for this type of steel pipe involves continuously crimping steel plates into a spiral shape and welding the edges of the plates together by internal and external submerged arc welding to form a spiral weld seam for the pipe. This type of steel pipe is characterized by having a spiral weld seam, and its high production efficiency makes it suitable for manufacturing large-diameter steel pipes.

Read MoreOur carbon steel pipe are used in a wide range of industries, as you can see, whether it’s construction, oil and gas transport, or power and piling jobs. We only make quality carbon steel pipe to help you run your business better.

Engineered for high-pressure and long-distance transportation, our pipes provide a secure and efficient solution for energy transmission.

Resistant to corrosion and extreme conditions, our pipes ensure the safe and reliable transport of various chemicals.

Designed to handle high-capacity water flow, our pipes support municipal and industrial water distribution networks.

Essential for power plant infrastructure, our pipes facilitate the transport of cooling water, steam, and other energy-related fluids

Built to withstand harsh marine conditions, our pipes are widely used in dredging projects, offshore construction, and underwater pipeline installations.

Our spiral steel pipes are used in foundations, bridges, and high-rises, offering strength, durability, and pressure resistance.

Our pipes play a vital role in long-distance transmission across various industries, ensuring efficiency, durability, and safety in demanding environments.

Steel pipes form the backbone of modern infrastructure, from transporting water and oil to providing structural support. However, their greatest enemy is always corrosion. Without protection, steel can succumb to rust, leading to leaks, structural failures, and costly replacements. This is where protective coatings come in—they are the pipe's shield. But with various coating types available, how do you choose the right one? This guide breaks down the most common types of coated steel pipes, their advantages, and their ideal applications to help you make an informed decision. Why Do Steel Pipes Need Coating? The Critical Battle Against CorrosionBefore diving into the types, it's essential to understand the "why." A coating is not just paint; it's a engineered barrier system that protects the pipe in two primary ways: Barrier Protection: It physically prevents corrosive elements like water, oxygen, and soil chemicals from reaching the steel surface. Cathodic Protection: Some coatings…

READ MORE

(Introduction)Spiral welded pipes are critical components in everything from piling and infrastructure to water transmission. However, the purchasing process is fraught with potential pitfalls that can compromise your project's integrity, timeline, and budget. A buying decision based solely on the lowest price often leads to the highest long-term costs. This guide will walk you through the most common mistakes engineers, project managers, and procurement specialists make and how to avoid them, ensuring your next purchase is sound, secure, and successful. Mistake #1: Prioritizing Unit Price Over Total Cost of Ownership This is, without a doubt, the most frequent and costly error. The Problem:It's tempting to choose the supplier with the lowest price per meter or ton. However, this initial saving can be illusory. A cheaper pipe often means: Inferior raw material (steel coil) quality, leading to faster corrosion and a shorter service life. Less stringent manufacturing controls, increasing the risk…

READ MORE

Manufacturing Spiral Submerged Arc Welded (SSAW) Pipes involves a continuous process. A strip of steel called the skelp forms at an angle. Then, it gets welded along the spiral seam. The skelp goes through rollers that bend the metal at an angle. This introduces internal and external welds using submerged arc welding. Modern automation and control systems greatly enhance the precision of angle measurements. They also improve the welding quality of SSAW pipes by ensuring homogeneity. These pipes are frequently used in applications like transporting water. They also have structural purposes in the construction industry. Quality Control Quality control in SSAW pipe manufacturing includes checks on the raw material, particularly the steel coil. During production, continuous monitoring of welding parameters, seam quality, and the pipe geometry is essential. Non-destructive testing, including ultrasonic and radiographic tests, is conducted to detect any defects. Final inspections involve hydrostatic testing and visual assessments, ensuring…

READ MORE

Looking for the right 3LPE coated pipe? Want to find a quality 3LPE coated steel pipe supplier? Keep reading—TUSPIPE understands your needs! We’ll not only explain what 3LPE coated pipe is but also provide premium solutions! What Is 3LPE Coated Pipe The Evolution of Triple-Layer Extruded Polyethylene Coated Pipes Before the mid-20th century, coated pipes used petroleum asphalt or coal tar enamel as anti-corrosion coatings. These coatings are low in cost, but their obvious drawbacks are poor thermal stability and insufficient mechanical strength. Subsequently, single-layer polyethylene (PE) coatings brought some progress. Though offering chemical resistance and excellent insulation, they failed to bond well with the inner steel pipe. Internal corrosion frequently occurred in such coated pipes. In the 1960s, FBE coated pipes gained widespread adoption. They achieved exceptional adhesion between the pipe and the fused epoxy powder coating. However, the 250-500μm chemical coating thickness was insufficient to provide adequate protection for the underlying steel…

READ MORE